Now that the water is a bit clearer (and warmer) it was time to break out the snorkel gear and check out the boat beneath the waterline! Fun stuff, eh?

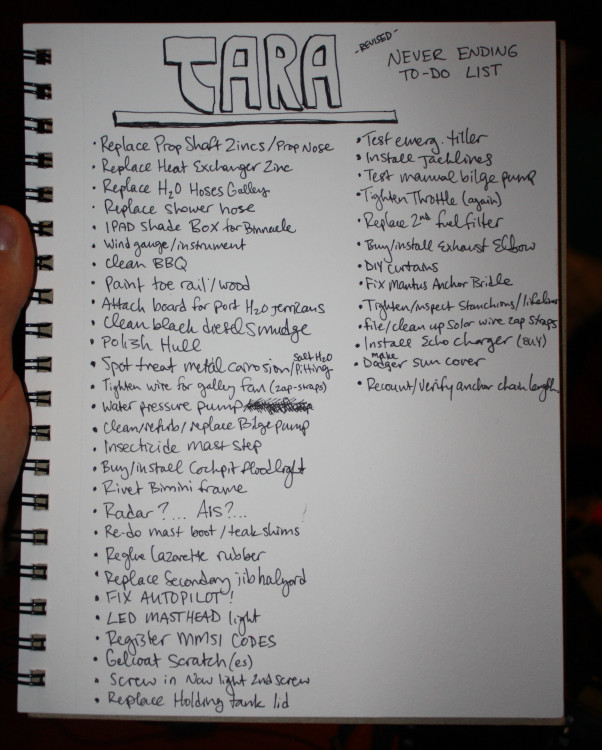

We discovered:

The good – The coat of antifouling paint we applied before we left is holding up great! No barnacles to be seen – woo hoo!

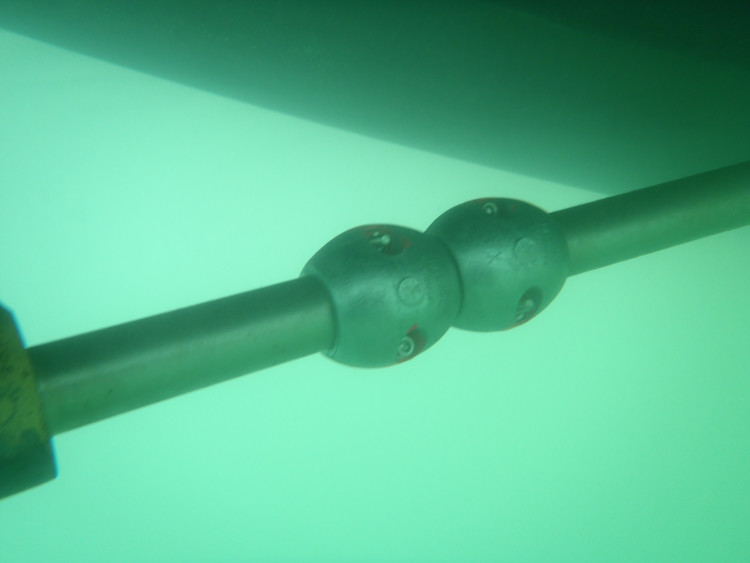

The bad – Our zincs (sacrificial metal that is supposed to corrode before your propeller does) have mostly corroded away…and by mostly, I mean MOSTLY. For sailors, it’s hard not to cringe at the sight of the photo below…

Crumbling away…

So today, was zinc replacement day  We didn’t want to go for a haul out, so this meant gearing up and getting in the water.

We didn’t want to go for a haul out, so this meant gearing up and getting in the water.

I learned a couple cool tricks via the interwebs:

– Tie string to all tools you plan on using underwater (lanyards around the wrist) – this was a no-brainer.

– Duct tape the anodes together (across one side of the split) to keep the halves from falling apart when trying to get it on the shaft – this one was actually really helpful because it would have been hard to tighten both screws in one breath of air

– Wear one glove on your left hand (assuming you’re right handed) to wedge bolts into when you’re diving…(no, not just because you’re trying to do your best underwater moonwalk)

– Paint nail polish in key areas to avoid corrosion around bolts

Tools of the trade

It’s impossible to look cool in a snorkel mask. Believe me, I tried.

Victory!

It was a major success getting the (2) new anodes on. I got to use my shorty wetsuit (though I probably didn’t need to), the snorkel gear, and tools…underwater! It felt good getting this one done. Officially crossed off the list, with more projects to come.